Demonstrating Industrial Electrification

The industrial sector accounts for about one-quarter of US greenhouse gas emissions but is categorized as very difficult to decarbonize. This is primarily due to the large amounts of energy and heat required for industrial processes, but there are many other barriers as well, including cost and lack of commercialized technologies. In an effort to reduce these barriers to industrial decarbonization, the Department of Energy recently announced a large amount of funding. Let’s explore!

Industrial Decarbonization Demonstration Program

At the end of March, the Department of Energy announced that it had awarded over $6 billion to 33 demonstration projects across the US to reduce greenhouse gas emissions. This came from a combination of funding from the Bipartisan Infrastructure Law and Inflation Reduction Act to the Industrial Demonstrations Program. Almost 80% of the selected projects are located in disadvantaged communities defined by the Justice40 initiative.

The goal of the program is to support new decarbonization technologies including energy efficiency, electrification, and alternative fuels and feedstocks such as clean hydrogen, as well as other approaches such as carbon capture. The program focuses on reducing emissions in high emissions industrial processes, including steel, aluminum and other metals, cement and concrete, chemicals and refining, food and beverage, pulp & paper, and other manufacturing. Although the Industrial Demonstration Program covers many decarbonization approaches, the rest of this discussion will focus on industrial electrification.

Industrial Electrification Is Not New

Before we get too far into the discussion, it is important to point out that industrial electrification is not new. We have been using electricity for industrial processes for over 100 years. A quick case study: Triscuits. I had always assumed that the brand name Triscuit referred to the cracker having three layers of woven wheat, but apparently, its name is a portmanteau for “Electricity Biscuit.” In the very early 1900s, Triscuits’ claim to fame was that they were manufactured in electric ovens powered by the hydropower station in Niagara Falls, which had only been built a few years before in 1895.[1]

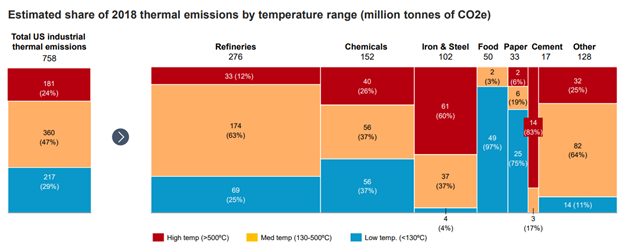

Since then, electric heating technologies have improved exponentially. According to a recent study by the Renewable Thermal Collaborative, heat pumps can be cost-effective in industrial processes under ~130ºC. This temperature range can cook Triscuits and be used in other food and beverage processes. It can also be used to create steam, which can be used in many industrial applications. The study found that this temperature range can cover more than 40% of industrial thermal emissions and this share will only increase as the technology continues to improve. Many other electric heating technologies also exist at various levels of commercialization, from traditional resistance to infrared, induction, and direct arc melting, among countless others. Even in cases where electric technologies can’t meet the full temperature needed for a process, it can be used to preheat process streams to reduce the load of the more carbon-intensive solution. The chart below shows the estimated share of 2018 US thermal emissions by temperature range. If a significant portion of low and medium heat processes can be electrified, it would represent a substantial reduction in industrial emissions.

Source: Renewable Thermal Collaborative

Barriers to Electrification

So what is holding industrial electrification back? The high first cost of the equipment and the low price of natural gas are the primary roadblocks, but there are many other barriers. Jan Rosenow, director of the Regulatory Assistance Project, recently put together a great chart outlining the barriers to industrial electrification (check it out!), categorizing them by economic, technological, infrastructure, and knowledge barriers. Many of the barriers are related to the newness of the technology: there are a limited number of manufacturers, the industrial sector is extremely heterogenous, and most facility and process require their own design which limits standardization. All of this represents major risks to the industrial facilities, who don’t want to be the first mover away from something proven to something unknown. The Industrial Demonstration Program helps with that by funding projects to demonstrate the feasibility of industrial electrification/decarbonization while also building out the knowledge in the supply chain.

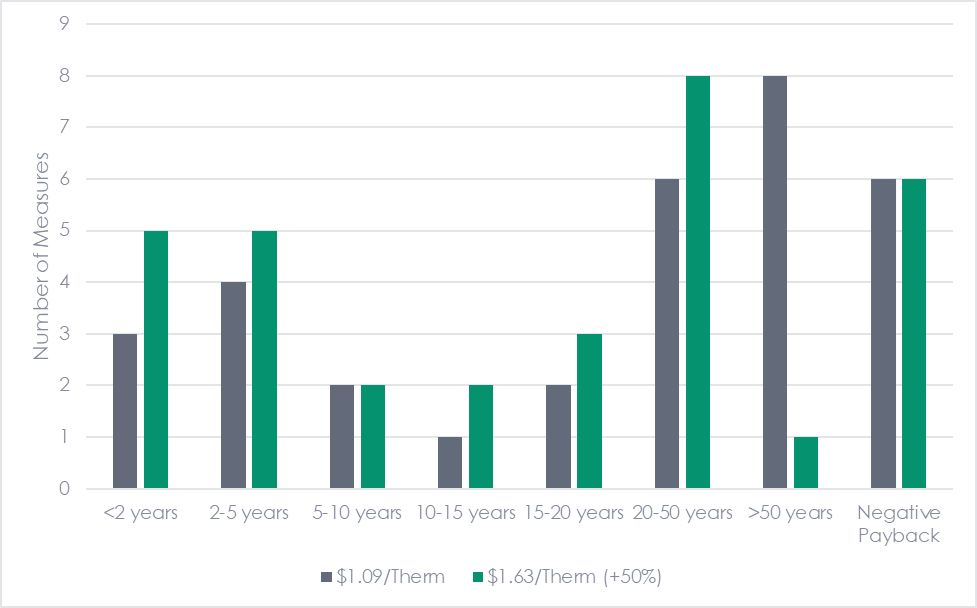

The barriers of high equipment costs and low natural gas rates were highlighted in a study Michaels Energy recently completed investigating electrification in the industrial and agricultural sectors in Iowa. We conducted detailed audits of seven facilities to identify potential electrification opportunities. We found that given the current fuel prices, the payback period for electrification in those facilities was too long to be feasible for most opportunities. Of the 32 identified measures, only 18 had positive simple payback periods of less than 50 years and only 7 had simple payback periods of less than 5 years, given the electric and natural gas prices at the time of the study. We conducted various sensitivity analyses and found that increasing the price of natural gas by 50% cut the expected simple payback for some measures, such as heat pumps, by half.

Figure 1. Simple Payback Period of Identified Electrification Measures at Select Natural Gas Prices

Of course, these case studies only looked at electrifying existing facilities. The cost of electrification is much more palatable for new construction, when processes can be designed from the bottom up rather than requiring a massive retrofit. The cost effectiveness of electrification also improves greatly for new industrial facilities when you consider potential natural gas constraints and the cost of millions of dollars per mile for new gas infrastructure.

Lowering the cost and payback period of industrial electrification and increasing the number of demonstration projects will go a long way in reducing barriers to decarbonization of the sector. And even if some high temperature processes are truly very difficult to decarbonize, the large majority of industrial emissions can be eliminated with existing technologies if supported and prioritized.

[1] This was a pretty big deal, as the Niagara Falls power station was the first hydroelectric power plant ever and the first decentralized generation station based on Nikola Tesla’s alternating current design. The AC design allowed the power plant to send electricity over 20 miles away to Buffalo. Previously, Edison’s DC-based power stations could only send electricity relatively short distances, so the generators needed to be located very close to the biscuit factories and other load.

.png)